Stainless Steel 304 Metal Corrugated Packing For Distillation

Column 500BX

Metal Perforated Corrugated Packing Description

Metal structured packing is a kind of packing arranged and stacked

in accordance with uniform geometry in the tower. The geometry of

the whole tower section is regular, symmetrical and uniform, and

the gas-liquid flow path is specified, which reduces the phenomenon

of channel flow and wall flow, and the pressure drop can be very

small. Under the same energy cost and pressure drop, it can provide

more specific surface area than random packing, and achieve higher

mass transfer and heat transfer efficiency in the same volume. At

the same time, due to the uniformity, regularity and symmetry of

its structure, when it has the same specific surface area as random

packing, its void ratio and flux is larger, and its comprehensive

processing capacity is much larger than tray tower and random

packing tower. After careful design, manufacture, installation and

operation of tower internals (such as gas-liquid distributor), the

industrial amplification effect is not obvious. In recent decades,

structured packing has been widely used in many towers in fine

chemical industry, perfume industry, oil refining, fertilizer,

petrochemical industry and other fields. Our company mainly

produces and supplies two kinds of metal structured packing,

corrugated orifice plate structured packing and wire mesh

structured packing.

Metal Perforated Corrugated Packing Detail Introduction

| Product name: | Metal Orifice Corrugated Packing | Brand Name: | TIANMA |

| Size: | 450Y,650Y | Place of Origin: | Pingxiang,Jiangxi, China (Mainland) |

| Dimensions: | h/mm:4.5 -6.5mm ;t/mm :0.1mm | Material: | SS304,SS316,SS316L,210,410 |

| Bulk Density: | 110-165kg/m3 | Usage: | Absorption/Scrubbing/Stripping/Tower Packing |

| Surface area: | 454-651m2/m3 | Certificate: | GB/T19001-2016 ISO9001-2015 |

| Pressure drop: | 1.52*10-4 Mpa/m | Packing: | Jumbo bag/Carton box/wooden pallet |

| Liquid load: | 0.2-.00M3/M2.H | Warranty: | Offer lifetime consultation on |

| Purity: | 0.9999 | Sample: | Free sample |

| Standard: | HG/T 4374-2012 | Mini Order: | 2 Cubic Meter |

| void fraction: | >97.6 % | Service: | OEM Manufacturing |

| Appearance: | Rectifying column | Terms of delivery: | EXW, FOB, CFR, CIF |

Metal Perforated Corrugated Packing Parameters

Metal Perforated Corrugated Packing Feature

1. The pressure drop of the structured packing is significant

Since the gas-liquid two-phase membrane contact in the structured

packing is different from the bubbling contact of the two phases in

the sieve tray, the pressure drop of the packed tower is only 1/4

to 1/6 of the sieve tray. For example, the operating resistance of

the tower on the structured packing is 3.5-4.2 kPa, the operating

pressure at the bottom is only 35-45 kPa, the lower tower is still

still using the sieve tray tower, and the operating resistance is

not changed, so the operating pressure of the lower tower is

correspondingly reduced by 0.05~ 0.06 MPa, generally 0.44 to 0.48

MPa, so that the shaft power of the air compressor can be reduced

by 5% to 7%.

2. High efficiency of structured packing separation

The lower the operating pressure of the upper column, the greater

the separation of oxygen, nitrogen and argon, especially the

separation of oxygen and argon. Generally, the extraction rate of

oxygen can be increased by 1% to 3%, and the extraction rate of

argon can be increased by 5%. 10%, practice has proved that the

oxygen extraction rate of air separation equipment has reached more

than 99%, and the extraction rate of argon has reached more than

80%.

The extraction rate of the distillation column depends to a large

extent on the amount of expansion air entering the upper column,

especially for the extraction rate of argon, so the isentropic

efficiency of the turboexpander and the supercharging of the

supercharger are continuously improved. The ratio is the key to

increasing the extraction rate of the distillation column.

3. The regular packing has a small liquid holding capacity

The volume of the structured packed column is generally only 1% to

6% of the column volume, while the holding capacity of the sieve

column is 8% to 10% of the column volume. The small liquid holding

capacity means that the liquid stays in the tower for a short time

and the operating pressure drop is small, which is beneficial to

the operation of the variable working condition. The structured

packing tower can be designed in the range of 40% to 120%. The

oxygen production of the upper tower of the 12000m3/h air

separation plant of Shanggang No. 5 Plant can be adjusted within

the range of 9000~14000mm3/h, and the operating load range is only

75%~117%.

4. Regular packing gap is large

The structured packing has a void ratio of more than 95%. In the

sieve tray tower, the orifice plate area accounts for 80% of the

tower section, and the opening ratio is 8% to 12%, which are far

less than the void ratio of the filler layer. For the same load,

the tower of the packed tower is smaller than the sieve tower; in

general, the cross-sectional area is only about 70% of the sieve

tower, which is advantageous for large-scale air separation

equipment.

5. The device startup time is greatly shortened

The starting process of the air separation equipment is no product

output operation, so shortening the starting time is one of the

ways to save energy and reduce consumption of the air separation

equipment. The starting time of the air separation equipment refers

to the time required to start the expansion machine to the oxygen

output. After the completion of the packing, the amount of liquid

held during normal rectification is greatly reduced, and the

start-up time of the air separation plant is greatly shortened.

After the conventional packing is used in the upper tower, the

amount of liquid held during normal rectification is greatly

increased. After the descent, the start-up time of the air

separation plant is greatly shortened, and the general start-up

time only takes 26 to 30 hours.

6. The oxygen content in the argon fraction is about 90%.

To reduce directly to 1~2×10-4% by cryogenic rectification, the

theoretical plate number of the rectification column needs about

180 pieces, the sieve plate plate needs about 300 pieces, and the

resistance is up to about 100 kPa. Obviously, the crude argon is It

is impossible to discharge the outside of the tower, and the height

of the structured packing is about 45m. The resistance is only 14

to 16 kPa, so the realization of the full rectification argon

process is possible.

Metal Perforated Corrugated Packing Application

1. Atmospheric rectification and vacuum rectification,application

fields similar to metal wire gauze packing and special technology

such as requiring titanium or aluminum gauze packing.

2. Substituting for random packing and revamping some tray towers

in approprite conditions.

3. Absorption reqiring low resisitance and distillation with heat

pump.

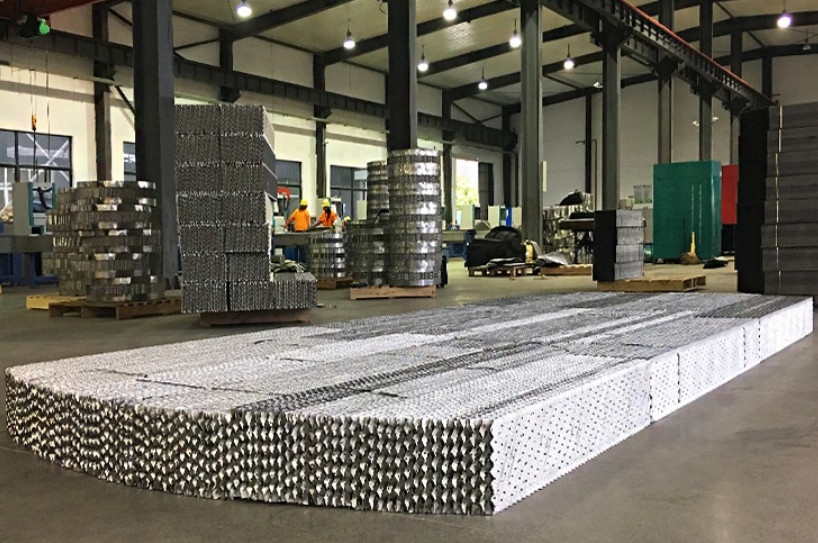

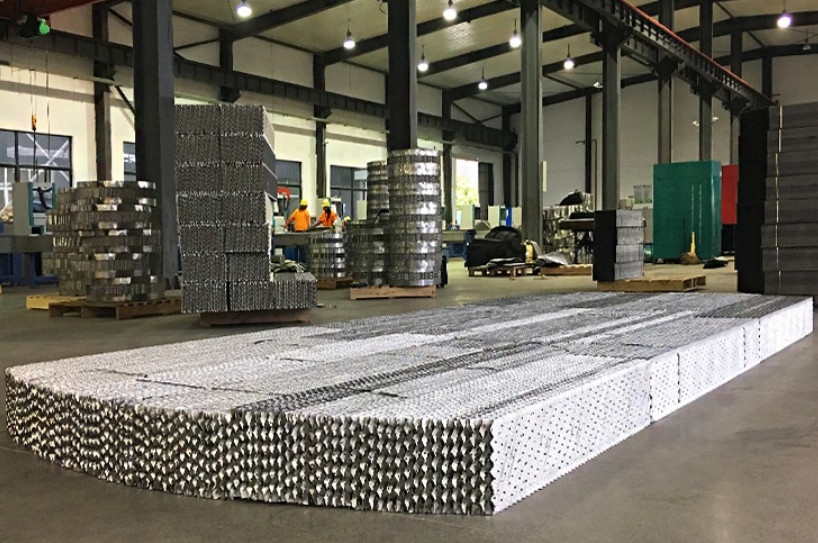

Production Show

Company Profile

1. Is your company a manufacturer or a trading company?

We are a manufacturer located in Anping County, China.

2. Do you have inport-export right?

Yes, we do. Our factory has been certificated as an import-export

enterprise.

3. What is your payment mode?

30% in advance and 70% before delivery by T/T, WESTERN UNION, L/C

or negotiated.

4. How about your packing?

We usually packed in plastic material inside and then wooden box

outside.

5. How long is your delivery?

Usually 10-20 days after order confirmed, according the quantity

ordered.

6. Is it sample available?

Yes, small pieces of sample are available in our company.